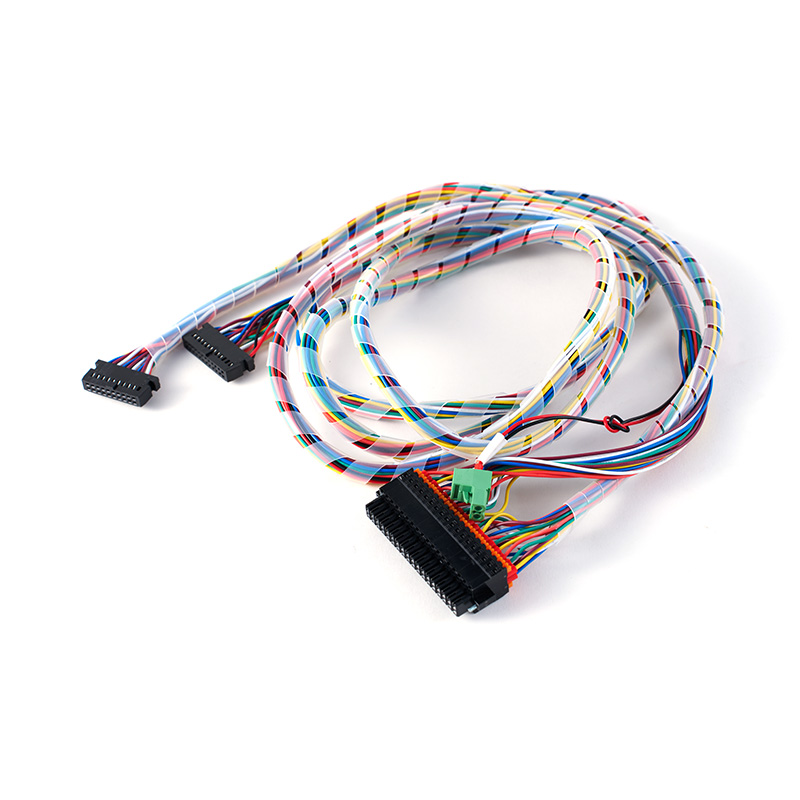

High-voltage power networks are built around a mix of structural planning, electrical engineering, and system-level coordination. As electricity demand grows and equipment becomes more sensitive to fluctuations, stability becomes a central design objective. Engineers must balance conductivity, insulation strength, thermal endurance, and installation methods to ensure that large electrical systems remain dependable in daily use. Components such as a Power Wiring Harness, a Power Cable Harness, or an Industrial Wiring Harness play significant roles in shaping how energy flows, how interference is controlled, and how safety standards are achieved. This article explores the essential design elements that contribute to stability, focusing on architecture, materials, routing practices, protective mechanisms, and system-wide planning.

The Importance of Robust Structural Architecture

High-voltage systems rely on a consistent and uninterrupted power path. Stability begins with the physical architecture of the wiring arrangement. A Power Wiring Harness offers a structured layout that reduces the risk of loose connections or random cable movement. By grouping wires according to function, engineers can keep signal paths predictable and easier to inspect.

A well-organized architecture also reduces the risk of electrical noise migrating between conductive paths. In complex facilities—whether industrial plants or utility installations—electromagnetic interference can easily disrupt sensitive devices. Through separation rules, shielding layers, and fixed routing, a Power Cable Harness helps maintain a clean environment where high-current lines do not interfere with low-signal wires.

In manufacturing lines and large machinery, a structured Industrial Wiring Harness ensures that cables exposed to motion, temperature changes, and vibration remain stable over long periods. Its clarity of layout also simplifies upgrades, system audits, and long-term maintenance.

Material Selection and Durability Requirements

Choosing appropriate materials is one of the most important elements of stability. High-voltage networks must withstand heat, mechanical stress, and chemicals without degradation. The insulation materials around a Power Wiring Harness must achieve a balance between flexibility and dielectric strength. If the cable is too rigid, installation becomes difficult; if it is too soft, it may not resist high-temperature environments.

A Power Cable Harness often uses multiple insulation layers, each with a different purpose. One layer may provide fire resistance, another may offer chemical protection, and another may reduce noise transmission. These materials work together to maintain consistent performance even when operating in demanding environments.

Likewise, an Industrial Wiring Harness used in factory systems must be prepared for oil exposure, abrasive dust, and continuous mechanical motion. The choice of sleeve materials, protective tubing, and binding techniques determines how well the assembly performs over years of service.

Routing and Spatial Planning

Routing, spacing, and cable separation strongly influence stability. Even small changes in distance between cables can reduce noise levels or improve cooling. Engineers consider factors such as bend radius, airflow, and mechanical support when planning the layout.

Below is a simplified table showing how routing decisions affect system performance:

|

Design Consideration |

Impact on Stability | Typical Implementation |

|

Cable Separation |

Reduces interference | Split routing channels or trays |

|

Bend Management |

Prevents stress damage | Controlled curves and support points |

|

Thermal Spacing |

Improves heat dissipation | Air gaps and heat-resistant barriers |

|

Vibration Isolation |

Protects connectors and joints | Cushioned clamps and reinforced ties |

A Power Wiring Harness benefits greatly from structured routing, especially when installed in cabinets or long-distance runs. Keeping high-voltage lines away from sensitive instrumentation avoids false signals and system delays.

Similarly, a Power Cable Harness with organized routing reduces the risk of insulation wear caused by friction. In high-energy distribution systems, even minor abrasion may cause arcing, so mechanical protection is critical.

For large machinery or automated production lines, the routing rules used in an Industrial Wiring Harness are often stricter. Dynamic movement and repeated bending require reinforced pathways and flexible sleeves to preserve long-term system integrity.

Electrical Protection and Safety Layers

High-voltage networks must incorporate advanced safety features to handle fault currents, surges, and unexpected load changes. Protective elements support both immediate safety and long-term stability.

Insulation Coordination

Insulation must be matched to expected voltage levels, environmental stress, and system layout. In a Power Wiring Harness, insulation coordination prevents flashover and helps maintain safe operating margins.

Shielding and Grounding

A Power Cable Harness often contains shielding, whether foil, braided mesh, or conductive tapes. These layers ensure signals remain stable and protect equipment from noise. Ground paths must be designed to carry fault currents safely without creating unexpected heat zones.

Overcurrent and Thermal Protection

A well-designed Industrial Wiring Harness may include built-in thermal layers, heat-resistant sleeves, or sensor-compatible routing that allows monitoring of temperature changes in real time. These mechanisms help maintain stability when the system approaches its thermal limits.

Connectors and Interface Quality

While cables carry energy, connectors determine how reliably that energy transfers from one device to another. Poor contact can trigger sparking, voltage drops, and localized heat.

Mechanical Reliability

A Power Wiring Harness may use locking mechanisms, seals, and reinforced housings to keep connectors stable under mechanical stress. In environments with vibration—such as industrial presses or rotating machines—connector fatigue is a common failure point without proper design.

Environmental Sealing

Moisture or dust infiltration can degrade electrical joints. A Power Cable Harness designed for outdoor or industrial use often includes sealing gaskets, moisture-resistant compounds, and protective boots around contact points.

Compatibility Across Components

Different devices within a facility may come from multiple manufacturers. An Industrial Wiring Harness must account for plug shapes, voltage ratings, pin configurations, and grounding arrangements to remain compatible across the system. Standardization helps maintain stable operation during equipment expansion or replacement.

Thermal Management and Heat Control

Heat is one of the biggest threats to long-term stability. High-voltage conductors naturally generate thermal energy, especially under heavy loads. Without proper dissipation, insulation materials degrade, conductors soften, and connectors weaken.

A Power Wiring Harness may incorporate heat-resistant materials and controlled spacing to reduce temperature buildup. The goal is to maintain a stable thermal environment even during peak usage cycles.

For heavily loaded systems, a Power Cable Harness may require additional cooling support, such as airflow channels or liquid-cooled components. In energy-intensive facilities like data centers or manufacturing plants, these methods help prevent overheating during extended operation.

An Industrial Wiring Harness must factor in localized heat sources such as motors, furnaces, or hydraulic systems. Placement, shielding, and heat-absorbing materials ensure the harness continues functioning in close proximity to hot machinery.

System Integration and Long-Term Maintenance

Stability is not achieved through design alone; it also depends on how well a system can be maintained over time.

Clear Labeling and Diagnostics

A structured Power Wiring Harness with clear labels and consistent color codes helps technicians diagnose issues quickly. This reduces downtime and prevents misinterpretation during inspections.

Scalability and Upgrades

As facilities expand, wiring networks often need to change. A modular Power Cable Harness supports smoother upgrades by offering predictable connection points and standardized routing channels.

Serviceability in Industrial Settings

In factories, downtime is costly. An Industrial Wiring Harness with organized connectors, accessible routing paths, and flexible sections supports rapid repair or replacement without disturbing nearby equipment.

High-voltage power networks depend on a combination of architectural planning, material quality, routing rules, thermal control, and interface reliability. Whether engineers are installing a Power Wiring Harness, assembling a Power Cable Harness, or deploying an Industrial Wiring Harness, the design considerations remain similar: stability requires thoughtful structure and durable construction. By integrating protective layers, ensuring consistent material performance, and planning for long-term maintenance, electrical systems can operate reliably even under demanding conditions.

English

English русский

русский Español

Español 中文简体

中文简体