For manufacturers, electrical engineers, and industrial integrators, a reliable Transformer Wiring Harness Factory is essential for producing organized, safe, and efficient transformer assemblies. Wiring harnesses are key components that connect transformer windings to external circuits while ensuring proper insulation, layout, and performance. Understanding the capabilities and services of a factory helps businesses choose a partner that can meet both technical and production requirements.

What Is a Transformer Wiring Harness?

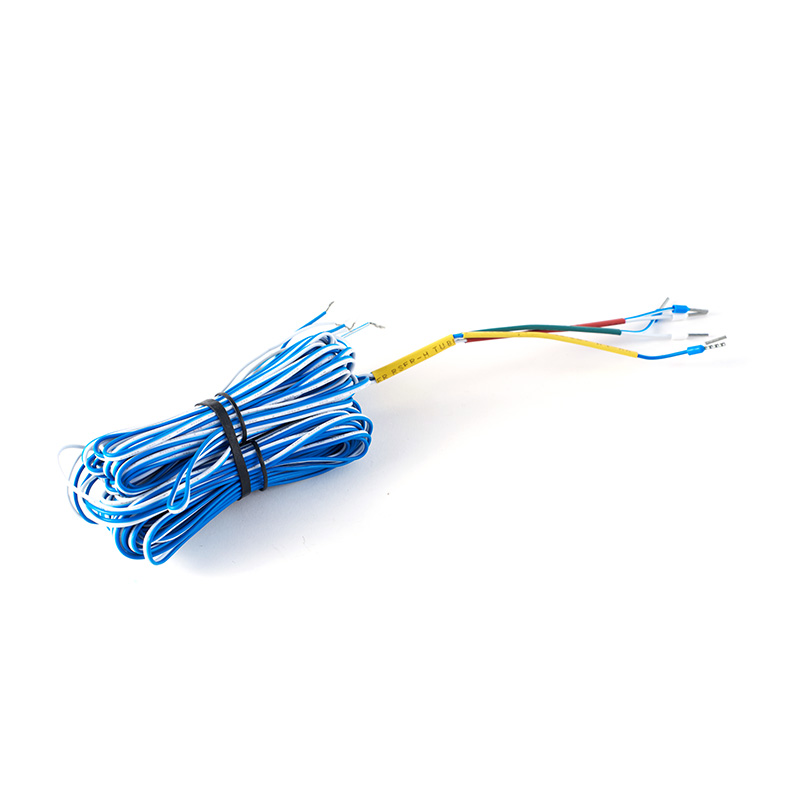

A transformer wiring harness is a pre-assembled network of wires, connectors, and protective insulation that facilitates the connection between a transformer and external equipment. These harnesses organize complex wiring, reduce installation errors, and improve the safety and longevity of transformers.

A Transformer Wiring Harness Factory specializes in designing and manufacturing these harnesses according to specifications, ensuring that each unit fits precisely and functions reliably in various electrical systems.

Manufacturing Expertise and Capabilities

A professional Transformer Wiring Harness Factory combines technical expertise with advanced production equipment. Factories often use automated wire cutting, crimping, and assembly machines to ensure consistent quality. Quality control measures, including electrical continuity testing, insulation checks, and thermal testing, ensure that every harness meets safety and performance standards.

Customization is a key feature of many factories. Buyers can specify wire types, lengths, connectors, insulation ratings, and other parameters to match specific transformer models or industry requirements.

Applications Across Industries

Harnesses produced by a Transformer Wiring Harness Factory are widely used in multiple sectors. Industrial transformers in power plants, factories, and distribution centers rely on precise harness assemblies to function efficiently. Commercial buildings and renewable energy systems, such as solar or wind power installations, use these harnesses to connect transformers to electrical networks safely. Even transportation systems, including trains and electric vehicles, may incorporate transformer harnesses for voltage conversion and control.

This versatility makes Transformer Wiring Harness Factory products suitable for both large-scale industrial applications and smaller, specialized projects.

Safety and Quality Considerations

Safety is critical when dealing with transformers and electrical systems. A Transformer Wiring Harness Factory implements strict quality controls to prevent short circuits, overheating, and insulation failures. Adhering to international standards, such as IEC or UL certifications, ensures that harnesses meet the required safety and performance benchmarks.

For businesses, sourcing harnesses from a factory with rigorous quality protocols reduces the risk of operational disruptions, costly repairs, and regulatory issues.

Benefits of Direct Factory Sourcing

Working directly with a Transformer Wiring Harness Factory offers multiple advantages. Buyers can access bulk orders with consistent quality, customization options, and technical support from engineers. Lead times are often shorter than ordering from distributors, and factories may provide additional services such as prototype testing, assembly guidance, and documentation for certification purposes.

For system integrators and OEMs, factory sourcing ensures that harnesses are compatible with transformers and other electrical components, facilitating smooth assembly and installation.

Maintenance and Longevity

Although transformer wiring harnesses are designed for durability, proper installation and periodic inspection are important. Ensuring that wires are securely connected, insulation is intact, and connectors are clean helps maintain system performance. Harnesses from a dedicated Transformer Wiring Harness Factory are generally easier to maintain due to standardized designs and high-quality materials.

A Transformer Wiring Harness Factory provides essential components that enhance the reliability, safety, and efficiency of transformer installations. By offering precise manufacturing, quality assurance, customization, and technical support, these factories serve both industrial and commercial clients effectively. Choosing a trustworthy factory ensures that transformer wiring harnesses perform consistently, support complex electrical systems, and contribute to the long-term stability of power networks.

English

English русский

русский Español

Español 中文简体

中文简体