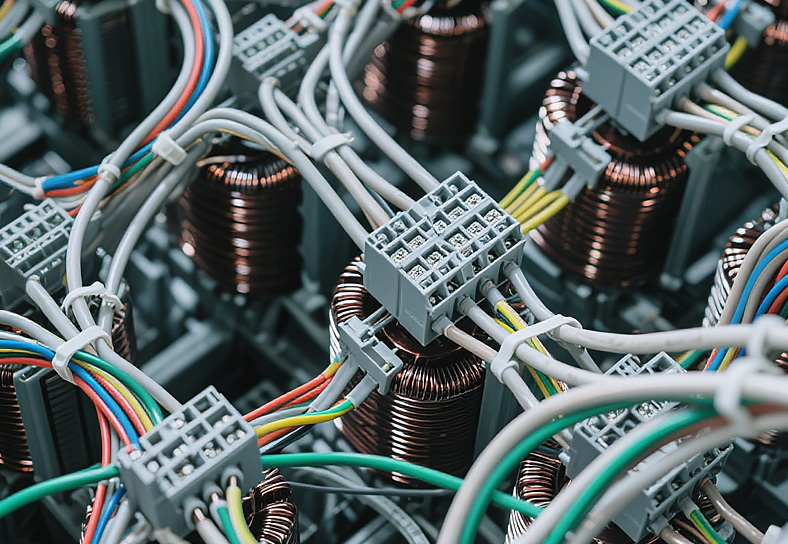

Modern machines—from industrial automation to construction equipment—depend on stable electrical performance. As systems become more compact and complex, wiring architecture plays an increasingly important role. Engineers now rely on an Integrated Wiring Harness, a Wire Cable Harness, and well-designed Wiring Components to maintain stable operation. These solutions ensure consistent power flow, reduce downtime, and simplify installation and maintenance.

Why Electrical Reliability Matters

Electrical reliability directly affects equipment uptime, safety, and performance. In complex machinery with hundreds of circuits, even a small fault can lead to cascading failures. Structured harness systems replace manually routed wires with organized assemblies that protect conductors, streamline installation, and reduce human error. By ensuring a stable electrical backbone, modern harness systems improve both operational efficiency and safety.

In industries such as robotics, aerospace, and smart manufacturing, even a momentary loss of electrical integrity can have serious consequences. Misrouted wires, loose connectors, or worn insulation can trigger system errors, reduce precision, or halt production lines. Harness systems are therefore designed not only to carry electricity but also to provide physical protection and simplify maintenance.

The Role of Integrated Wiring Harnesses

An Integrated Wiring Harness combines multiple circuits into a single, organized assembly. This structured approach reduces errors, prevents abrasion, and protects wires from vibration, heat, and chemical exposure. Modern harnesses also make troubleshooting easier. Technicians can trace faults without checking each wire individually, reducing maintenance time and minimizing downtime.

Integrated wiring harnesses also help standardize production processes. By assembling harnesses in controlled environments, manufacturers can verify quality, test electrical continuity, and apply protective coatings before installation. This level of pre-assembly reduces the likelihood of defects during field deployment and ensures that each machine receives consistent wiring quality.

Wire Cable Harness for Power and Signal Stability

A Wire Cable Harness organizes cable groups to support both power distribution and signal integrity. By routing cables along consistent paths, the harness reduces voltage drops, improves mechanical strength, and helps maintain stable operation in moving parts or environments with vibration.

In addition to mechanical stability, wire cable harnesses can integrate shielding to reduce electromagnetic interference (EMI). In complex equipment, signals from one circuit can disrupt others, leading to errors or unexpected behavior. Properly arranged wire cable harnesses, combined with shielding layers, help prevent such interference, keeping sensors, controllers, and motors operating reliably.

Wire cable harnesses are also flexible in design. Modular layouts allow engineers to adjust lengths, branch points, and connectors for different machine models. This adaptability saves both design and assembly time while maintaining consistent electrical performance across a range of devices.

Wiring Components as the Foundation of Reliability

High-quality Wiring Components—including connectors, terminals, and accessories—ensure stable electrical connections. These components reduce resistance, prevent accidental disconnection, and protect sensitive sensors from interference. They also support reliable power distribution to motors, controllers, and other critical elements.

Connectors, for example, are often designed to resist vibration and moisture, ensuring long-term reliability in demanding environments. Terminals are selected for their contact consistency and corrosion resistance, and accessories such as grommets and clips help secure wiring paths. Together, these Wiring Components create a system that supports both mechanical and electrical stability.

Proper planning of wiring components also allows for future upgrades. Modular connectors and standardized terminals make it easier to replace sections, add new sensors, or update circuits without extensive rewiring. This forward-thinking design reduces long-term maintenance costs and increases equipment adaptability.

Coordinated Systems Improve Long-Term Stability

When an Integrated Wiring Harness, a Wire Cable Harness, and carefully chosen Wiring Components are used together, the benefits multiply. Coordinated design reduces electromagnetic interference, simplifies maintenance, and increases operational consistency. Pre-assembled harnesses allow technicians to replace or upgrade sections quickly without extensive rewiring.

Table: Functional Contributions of Harness Systems

| System Type | Key Role |

Contribution to Reliability |

| Integrated Wiring Harness |

Multi-circuit organization |

Reduces wear, simplifies diagnostics |

| Wire Cable Harness |

Cable routing |

Supports power integrity, mechanical stability |

| Wiring Components |

Connectors, terminals |

Maintains secure connections, reduces interference |

This table highlights how each component contributes separately while supporting the overall system.

Applications in Real Equipment

- Industrial Robots: An Integrated Wiring Harness keeps multiple circuits organized within the robot arm. A Wire Cable Harness manages cable movement, and robust Wiring Components ensure sensor and motor reliability. In high-speed operations, these harness systems prevent miscommunication between sensors and controllers, allowing precise movements without interruption.

- Construction Equipment: Machines like excavators and cranes operate in harsh environments. Harness systems protect circuits from dust, vibration, and moisture, reducing the risk of failure. The combination of structured harnesses and durable components ensures that power and signal paths remain intact even under rough handling.

- Smart Manufacturing Lines: Coordinated harnesses ensure reliable communication between controllers, sensors, and actuators, minimizing downtime and maintaining production efficiency. By reducing errors caused by loose wires or interference, the systems support stable data flow and consistent machine performance.

- Medical Devices: Sensitive equipment such as imaging machines and diagnostic tools rely on precise signal transmission. Wiring components integrated into harnesses reduce noise and protect circuits, contributing to accurate readings and patient safety.

Design Considerations for Reliability

Environmental stress, temperature extremes, and compact spaces are common challenges. Selecting appropriate insulation, routing strategies, and protective layers in an Integrated Wiring Harness ensures longevity. Similarly, a Wire Cable Harness must accommodate movement without strain, while high-quality Wiring Components guarantee secure electrical contact.

Engineers must also consider maintainability. Modular designs, clearly labeled circuits, and accessible connectors reduce service time and make troubleshooting more efficient. Equipment that can be maintained quickly is less likely to experience prolonged downtime, which directly supports operational efficiency.

Lifecycle planning is another key factor. By anticipating wear points and using protective routing, harness systems can extend the operational life of equipment. This forward-thinking design minimizes replacement costs and ensures stable performance over years of use.

Modern harness systems—combining Integrated Wiring Harnesses, Wire Cable Harnesses, and reliable Wiring Components—play a vital role in ensuring stable operation in complex equipment. By organizing circuits, protecting conductors, and maintaining secure connections, these systems improve electrical reliability, simplify maintenance, and support consistent performance. In industries where uptime and safety are critical, thoughtful harness design is a key factor for long-term success.

Through careful integration, structured routing, and quality components, engineers can create machines that operate reliably in harsh conditions, remain easy to service, and adapt to evolving technological needs.

English

English русский

русский Español

Español 中文简体

中文简体